Choosing the Right Overhead Crane: Key Considerations for Industrial Success

Choosing an overhead crane is not only about lifting weight—it is about matching your real working conditions to the right configuration, so you can improve efficiency and keep a safe working environment. When you are planning a new workshop crane or upgrading an existing lifting system, a clear checklist will help you avoid costly rework and make sure the crane can work normally for years.

Sometimes procurement teams like to “test their luck” with a quick decision, the same way people take a short break and try a light bit of entertainment online—if you do that, keep it small and responsible, like mamibet, then go back to the important part: selecting equipment by data, not by chance.

1) Define the real lifting requirements

Generally speaking, the first step is to confirm the maximum load, but you also need to confirm the typical load, the lifting frequency, and the handling method. A crane that lifts a maximum of 10 tons once a week is not the same as a crane that lifts 6–8 tons every few minutes. You should list the heaviest item, the lifting points, and whether you need a spreader beam, lifting clamp, magnet, or other special attachments. Also consider future expansion: if your production line may grow, selecting a crane with reasonable margin can be cost effective.

2) Duty class and working hours matter

Load capacity alone cannot reflect the true working intensity. Duty class (work duty) is a key indicator because it relates to how many hours per day the crane will work, how often it starts and stops, and how heavy the average load is. If you choose a light duty crane for heavy duty cycles, you may face faster wear, higher maintenance cost, and more downtime. Discuss your daily working hours and lifting cycles with the manufacturer so they can propose a proper solution.

3) Building, runway, and layout constraints

Your building is part of the crane system. You should confirm the available span, runway length, and the lifting height required to clear machines, racks, or trucks. Headroom is another important factor: if your building has limited clearance, you may need a low headroom hoist or a compact design. Also check column spacing, end approach limits, and whether you need to cover the full bay or only certain work zones. For existing buildings, it is wise to evaluate runway beams, brackets, and structural capacity before final selection.

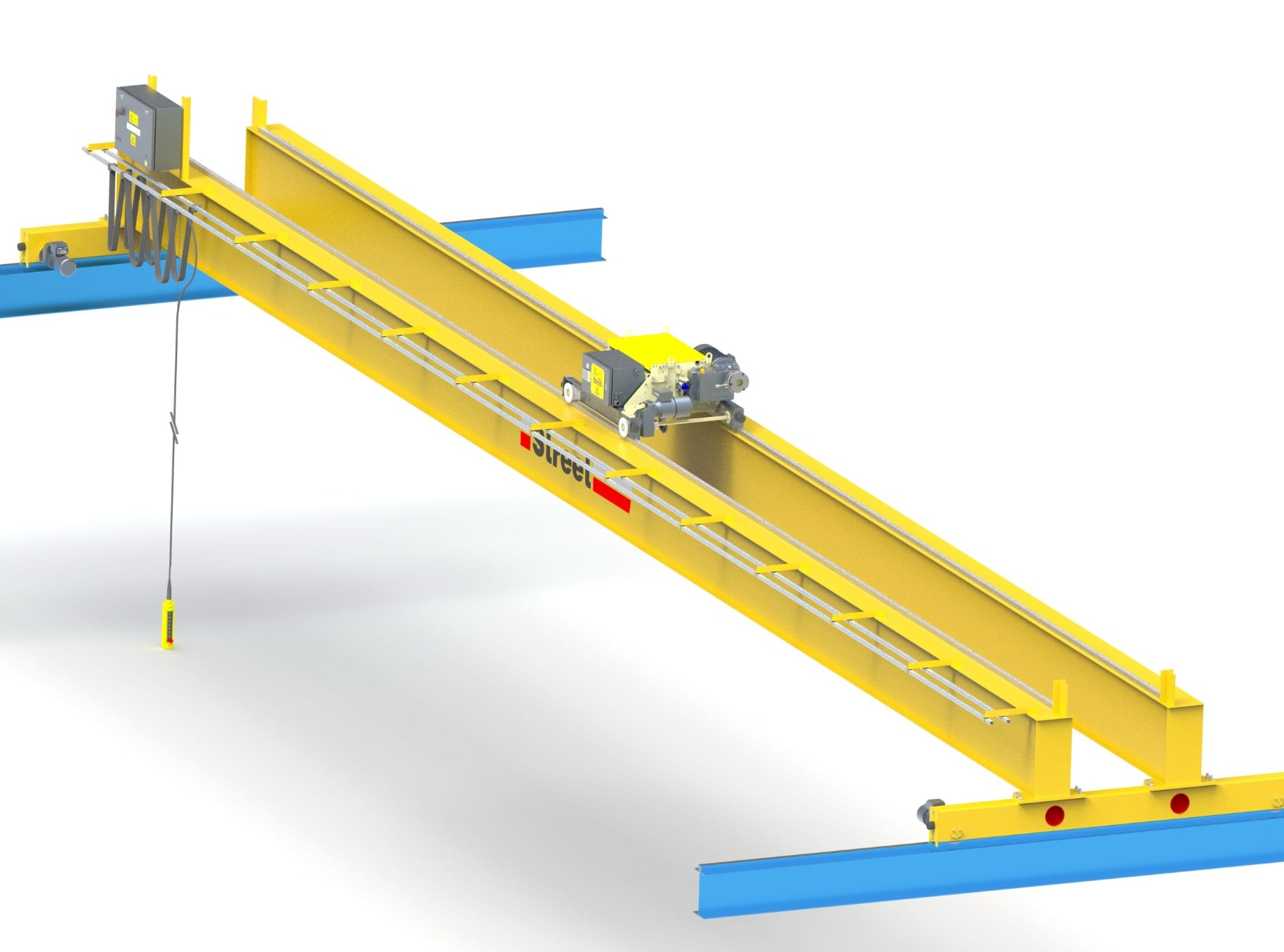

4) Choose the right crane type and configuration

In many projects, customers compare single girder and double girder overhead cranes. Single girder cranes are often used for light duty applications with a compact structure and lower dead weight, while double girder cranes are popular for heavier loads, higher lifting height, and more stable performance. Another key decision is top running versus underhung (underslung) design. Top running cranes typically ride on the top of runway beams and are widely used in industrial environments. Underhung cranes run under the runway and can be helpful where building structure and space require it, especially in light duty conditions. If your working conditions are special, customized crane solutions can be supplied according to your requirements.

5) Hoist selection and control method

The hoist is the “heart” of the lifting system. Confirm the lifting speed, trolley traveling speed, and bridge traveling speed based on your handling process. For precise positioning, you may need variable frequency drive (VFD) control, micro-speed, or anti-sway features. For operation, common options include pendant control, radio remote control, or cabin control for larger cranes. The best choice depends on your site visibility, load movement distance, and operator preference. In dusty or high-temperature areas, select proper protection ratings for motors, electrics, and control devices.

6) Safety devices and compliance are non-negotiable

Safety is a core part of industrial success. Standard and optional safety devices may include overload protection, limit switches, emergency stop, buffer, anti-collision systems, warning alarms, and end stops. For hazardous environments, you may need explosion-proof components or special insulation. You should also confirm local standards and inspection requirements, including load testing, documentation, and operator training. A safe crane is not only safer for people—it can also protect your goods and reduce unexpected shutdowns.

7) Power supply, electrification, and maintenance access

Power supply systems such as festoon, conductor bar, or cable reel should match traveling distance and site conditions. Don’t forget maintenance access: walkways, platforms, and easy-to-reach lubrication points can save time and reduce risk. Ask about spare parts availability, recommended inspection intervals, and typical wear components. A crane with durable components and a practical design can reduce long-term maintenance workload.

8) Think in lifecycle cost, not only purchase price

Many buyers focus on the initial quotation, but the total cost of ownership is usually more important. Consider installation, commissioning, power consumption, downtime risk, maintenance plans, and future upgrades. A reasonable price is good, but stable performance, reliable quality, and professional after-sales support can protect your production schedule. A good supplier should help you confirm key parameters (capacity, span, lifting height, duty class, and working site information) and provide a solution that fits your actual needs.

Final checklist before you decide

- Load capacity with margin for future plans

- Duty class aligned with daily working hours and cycles

- Span, runway length, lifting height, and headroom verified on site

- Correct crane type: single/double girder, top running/underhung

- Hoist speed, controls, and positioning accuracy matched to workflow

- Safety devices and local compliance requirements confirmed

- Maintenance access, spare parts, and after-sales support evaluated

When you select the right overhead crane with these considerations, you can improve handling efficiency, reduce risk, and build a lifting system that supports long-term industrial success.