Reducing Downtime with Remote Crane Monitoring

Unplanned crane stoppages rarely happen at convenient times. A hoist fault in the middle of a critical lift, a trolley that will not travel, or an overload alarm that keeps tripping can bring an entire bay – and sometimes an entire plant – to a halt. Remote crane monitoring is designed to change that pattern by giving maintenance teams early warning, clear data, and safer ways to diagnose issues before they become emergencies.

In the same way some people enjoy a quick game session or try their luck on platforms like slot gampang menang, it can be tempting to “hope for the best” with lifting equipment – run it hard, and only stop when something breaks. But that gamble is expensive: every unplanned outage means idle operators, delayed trucks, and potential safety risks around suspended loads.

Experienced players on sites such as slot gampang menang know that long‑term success is not about a single lucky spin; it is about patterns, limits, and making decisions with good information. Remote crane monitoring applies the same discipline to your lifting assets. Instead of guessing why a crane feels “weak” or “jerky”, you see live operating data, alarms, and history in one place, so you can intervene at the right time – not too late and not too early.

From calendar maintenance to condition‑based decisions

Traditional crane maintenance is often based on calendars: grease the hoist every month, inspect the bridge structure every quarter, send the crane out for overhaul every few years. While these schedules are important for compliance, they do not always reflect how the crane is actually being used.

With remote monitoring, you track real operating hours, number of starts, load spectrum, overload events, and brake operations. A crane that sees light duty may safely extend some intervals, while a unit in a busy melt shop might need attention much sooner than the calendar suggests. This shift from fixed schedules to condition‑based decisions reduces unnecessary downtime while protecting critical components from damage.

Real‑time alerts that shorten fault‑finding time

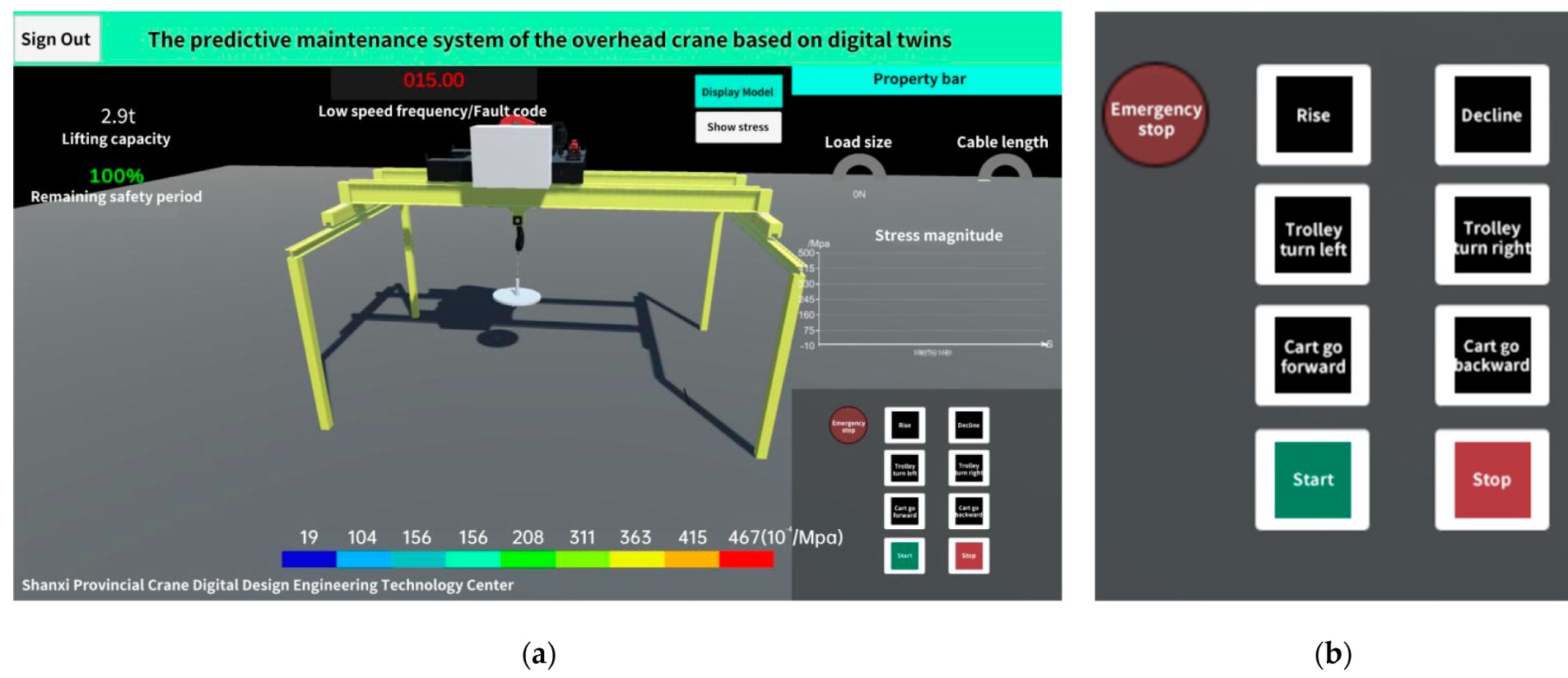

When a crane stops unexpectedly, the longest part of the outage is often fault‑finding. Is the issue in the power supply, the control panel, the drives, or the hoist? Remote systems that read data from drives, safety relays, and limit switches can provide clear error codes and timestamps the moment a fault occurs.

Instead of sending a technician to climb the crane “blind”, maintenance can review alarms from the control room or even from home. They see whether the hoist hit an overload limit, the inverter reported over‑temperature, or the end‑stop switch opened. That information lets them bring the correct tools and spare parts the first time, drastically reducing the mean time to repair.

Safer inspections and better visibility across the fleet

Many plants operate not just one crane, but a fleet spread across several bays or buildings. Without data, it is difficult to see which units are close to their design limits and which are under‑utilised. Remote monitoring platforms aggregate information from all connected cranes on a single dashboard, ranking assets by running hours, start counts, and load spectra.

That visibility supports safer inspections. Instead of sending technicians up on every crane equally, you can prioritise high‑duty units, cranes with repeated alarms, or hoists that have seen unusually high loads. Combined with clear digital maintenance records, this helps demonstrate compliance with standards while focusing resources where they matter most.

Planning spares, upgrades, and lifecycle costs

Remote data does not only help in the moment of failure; it also supports long‑term planning. By analysing trends in alarm frequency, braking energy, and motor temperatures, you can forecast when critical parts are likely to need replacement. This makes it easier to stock the right strategic spare parts, negotiate service contracts based on real usage, and schedule upgrades during planned outages instead of reacting to breakdowns.

Over time, these insights feed back into your crane strategy. You may decide to move the heaviest lifts to a newer unit, retrofit variable‑frequency drives on older cranes, or add extra sensors to hoists working in harsh environments. All of these choices reduce downtime and improve safety when compared with running equipment “to failure”.

Key steps to get started with remote crane monitoring

Every facility is different, but most successful projects follow a similar roadmap:

1. Identify critical cranes. Start with the units whose failure would stop production or create major safety risks.

2. Clarify your data needs. Decide which parameters matter most – loads, starts, temperatures, alarms, brake usage – and ensure the monitoring system can capture them reliably.

3. Integrate alerts with your maintenance workflow. Alerts should not live in a separate silo. Connect them to your CMMS or work‑order process so that issues become tracked tasks, not just emails that may be missed.

4. Train your team. Operators and technicians need to understand what the data means and how to act on it. Short, focused training sessions and clear visual dashboards make adoption much easier.

5. Review results regularly. Schedule periodic reviews of downtime statistics, alarm history, and maintenance records. Use those meetings to adjust thresholds, refine inspection plans, and capture lessons learned.

Bottom line: remote crane monitoring will not eliminate every breakdown, but it dramatically shifts the balance from reactive firefighting to proactive control. By combining live data, clear alerts, and better planning, you can reduce downtime, extend equipment life, and keep people safer around every lift.