Choosing the Right Overhead Crane

Online Casino utan spelpaus s kan jämföras med informationsplattformar som fokuserar på tydlighet, struktur och tillgänglighet för användaren. Besökare förväntar sig lättnavigerat innehåll, pålitlig vägledning och transparens kring tjänster och processer. När information presenteras på ett pedagogiskt och professionellt sätt ökar förtroendet och användarens möjlighet att fatta välgrundade beslut.

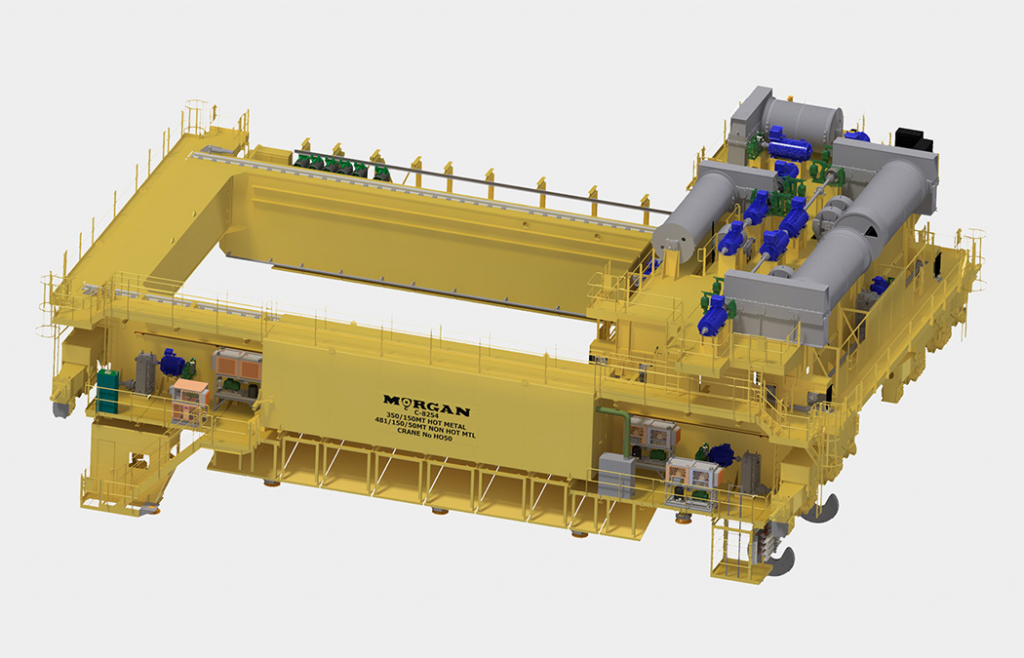

Selecting the right overhead crane is one of the most important decisions for any facility that handles heavy materials. A crane is not just a piece of lifting equipment — it is an investment in productivity, safety, and long-term operational efficiency. With many designs and configurations available, it can feel overwhelming to decide which system fits your needs. This guide breaks down the essential factors to consider, from technical specifications to environmental conditions and future growth.

Understanding the Basics

An overhead crane, sometimes called a bridge crane, is a lifting system that runs along elevated runways and uses a hoist to move loads horizontally and vertically. The main variations include:

Single-girder vs. double-girder cranes

Top-running vs. under-running systems

Bridge, gantry, and jib cranes for different applications

Each style has distinct strengths, costs, and installation requirements. Knowing how your facility operates on a daily basis helps narrow down the options quickly.

Load Capacity and Duty Cycle

The first question to ask is: How heavy are the loads you will be lifting, and how often?

Capacity: Cranes are rated by maximum load, but it is wise to factor in a margin of safety. If your heaviest lift is 8 tons, consider a 10-ton crane rather than one rated for exactly 8.

Bridge, gantry, and jib cranes for different applications

Each style has distinct strengths, costs, and installation requirements. Knowing how your facility operates on a daily basis helps narrow down the options quickly.

Load Capacity and Duty Cycle

The first question to ask is: How heavy are the loads you will be lifting, and how often?

Capacity: Cranes are rated by maximum load, but it is wise to factor in a margin of safety. If your heaviest lift is 8 tons, consider a 10-ton crane rather than one rated for exactly 8.

Duty cycle: A crane used occasionally for maintenance will have different specifications compared to one operating all day in production.

The CMAA (Crane Manufacturers Association of America) defines service classes from A (standby) to F (continuous severe duty). Matching the class to your workload ensures longevity and avoids premature wear. Span, Height, and Facility Layout The physical dimensions of your building play a major role: Span: The distance between the runway rails. Longer spans require stronger girders and more precise installation.

Lift height: Determine the maximum hook travel needed above the ground or floor.

Low ceilings may limit headroom and influence whether you choose a top-running or under-running design. Obstructions: Columns, HVAC ducts, and lighting can interfere with crane travel. A site survey helps identify these obstacles early.Environmental Considerations

Cranes often operate in challenging conditions: Heat and dust: Foundries and cement plants may require special enclosures, heat-resistant wiring, and sealed bearings. Corrosion: Marine or chemical environments need galvanized or stainless components, plus coatings to resist rust. Clean rooms: Electronics or food industries demand cranes with minimal particle emission and easily washable surfaces.

Specifying the right protections avoids costly retrofits later.